shirt construction

All fabrics are decatized (washed) and ironed before any other operation in order to give stability to the fabric, the collar and the cuffs.

The Client’s mesures are taken directly by the owner, Carmen, or by her daughter Roberta.

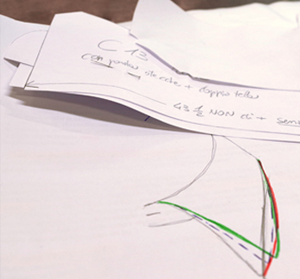

Afterwards they will create the paper pattern on the needs of the Client.

The different parts of the shirt pattern are exclusively hand-cut.

The sewings are made with a pure cotton thread, 10 points per centimetre and blind-stitchings.

The collar and the cuffs are made of pure cotton cloth, sewed and non-adeshive, following the old tradition, in order to avoid gatherings and ungluings.

The armhole is sewed offset from the shirt side seam in order to obtain a better wearability.

The bottons are made of the best Australian mother-of-pearl and they are exclusively hand-sewn.

On Client’s demand the shirt can be embellished by hand-sewn monograms, buttonholes and finishes.

The result is an unquestioned high-class product, created with extremely high-quality criteria, attention to every detail and that will stand the test of time.

The work we do on our bespoke shirts is the consequence of more than 40 years of experience and dedication.

our BESPOKE shirts

paper pattern

exclusively hand cut

hand-embroidered monogram

monogram

HAND-EMBROIDERED

Once the paper pattern is created,

we cut it to have a muslin trial shirt.

The drawing

and cutting process is handmade.

10 stitches per centimetre

Little stitches sewings

and internal non-adhesive

cotton clothes make

our shirts last longer.